By Bradley R. Jakubowski and John C. Fech

Regardless of the geographic location of the field(s) being managed, as winter approaches there are some important activities to tend to. These include actual on-the-field procedures, as well as “on the drawing board” planning and management sessions. Though the actual dates will need to be adjusted based on the locale, the common thread to all of them is the mindset of recognition of a change in season, weather conditions and in most cases, field usage.

Fertilization

To maximize uptake and utilization of various nutrients, keeping the growth rate in mind as fall transitions to winter is a key consideration for both application rate and formulation. Drawing on information discovered in recently published research studies by Dr. William Kreuser and others, the practice that should be followed is to lightly fertilize actively growing grass with quickly soluble nitrogen. This important technique guides us to apply only the amount that can be absorbed before turf plants enter dormancy for the winter, or, in the case of tropical turf, greatly reduce growth rate.

As well as the amount, the formulation or solubility is influential in the winterization process. Avoiding slow-release products ensures that little to no fertilizer will be carried over to the following spring, which greatly limits the amount of N moving downward in the soil profile, volatilizing to the atmosphere or moving laterally off site.

Nourishing newly seeded areas is especially important in mid to late fall, in that the goal is for the new stand to develop an extensive root and rhizome system. As with fertilization programs in spring and summer, looking to soil test results for guidance will provide useful information regarding other nutrients such as phosphorous, potassium, iron and magnesium. It’s crucial to compare apples to apples in this case; mid-fall soil tests from two years ago will provide the best comparison and baseline information. Because soil temperatures and moisture levels greatly influence existing nutrient release rate and availability, spring and summer test results are much less comparable/applicable.

Irrigation system blowout

The phrase “getting caught with you pants down” is perhaps the most descriptive of the need to remove the lion’s share of the water from sprinkler lines, valves and mains. All but the newest of sports field managers and crewmembers know that this means connecting an air compressor to the system at the appropriate pressure for the appropriate time, and watching all the spray heads and various other orifices for the eventual moisture removal and pressure release; however, several other related management techniques provide guidance for easier implementation.

There are rules-of-thumb that can be used when blowing out your irrigation system:

1. Whenever possible, use an air compressor with a minimum capacity of 100 cubic feet per minute (cfm) (Figure 1). This allows you to stay close to the 50-psi speed limit (keeping your air pressures between 45 and 55 psi) and minimize potential damage to your piping and sprinkler heads. Our tendency is to increase the air pressure to speed up the blow-out process with a lower-capacity compressor.

Air can exit your sprinkler 10 times faster than water, which, in turn, causes them to ratchet back and forth extremely fast – potentially damaging the internal mechanisms of your sprinkler heads (Figure 2).

Remember, it is NOT required to remove every drop of water from the system or until you have a an extremely fine or no mist. Doing so can result in catastrophic failure of the sprinkler (Figure 3).

So, when you first start to see your sprinklers expelling a fine mist instead of larger water droplets or a stream, it is time to move to the next controller station.

2. A high-flow pressure regulator that is independent of the air compressor to prevent damaging sprinkler heads could also be installed. The pressure regulator should be installed between the compressor and the main connection point.

3. Start with the sprinklers closest to the connection point and work away until all heads have been blown out. While blowing out a second time could lead to more water getting out of the system, you run the risk of causing more damage to the sprinklers – especially on high spots, such as hills, where added pressure could build up.

4. Don’t forget about quick-coupler connections. Each one needs to be blown out.

5. As sprinkler heads nearest the air source sputter and exhaust air, it is helpful to have helpers available who can manually push pop-up nozzles back down into their housings and stand on them (carefully) to direct pressurized air to the downline heads.

6. Make sure water is removed from any backflow prevention devices and their isolation ball valves are cracked open for the winter.

7. This is a good time to make notes of any broken or poorly functioning sprinkler heads to be repaired or replaced in the future.

Figure 4 shows a zone of three sprinklers being blown out. The two on the left are approaching a point where they have evacuated sufficient water for successful winterization. and someone could carefully press those down to speed up the process for the remaining sprinkler on the right.

As the time for a potential hard freeze draws near, keeping close tabs on the weather forecast is essential daily routine. Thirty-year average frost and freeze dates are a good place to start, but only serve as a reference. Real value can be obtained by installing and utilizing a simple weather station on site, especially if the field(s) are a fair distance from heat-retaining substances such as parking lots and office buildings. These days, weather stations are not expensive, with simple weather stations starting at around $150, and more sophisticated systems in the $500 range. Considering the low point of entry, the return on investment is substantial. The bottom line is that these tools provide localized information on soil temperature and a host of other weather conditions such as relative humidity and wind speed, which is essential when it comes to managing foliar turf and ornamental diseases.

Finally, matching field use schedules to blowout procedures is helpful as it takes two to four hours total to blow out the average sports field (football field); and while several air compressors may be available, most managers don’t carry one per field. Starting the process with fields that have concluded usage for the year, then moving to fields hosting later games will maximize time and labor inputs.

Aeration

Generally, mid to late fall is a time to avoid aeration, as opening up the turf shoot-root-thatch-mat interface close to the onset of cold weather is dangerous indeed. Cold weather and strong early winter winds can easily result in permanent damage from direct cold temperature injuries and desiccation.

However, if aeration has been performed in the weeks preceding as a step in obtaining seed-to-soil contact, it’s important to keep this open profile in mind as any late-fall topdressing operations are performed. Practices such as heavy sand additions and geotextile turf cover installation may need to be modified if aeration was implemented earlier in the season.

Planning mapping weed control for 2023

Gathering and identifying specific locations of weed infestations is a key late fall operation that pays big dividends in the winter and spring (Figure 5).

After all, if you want to fix or buy something, you have to identify the exact nature of the item you’re dealing with. That applies to controlling sycamore tree diseases; it also applies to controlling goosegrass, carpet weed, crabgrass and plantain. In the short term, one of the payoffs is determining which weed control products to buy for the upcoming calendar year.

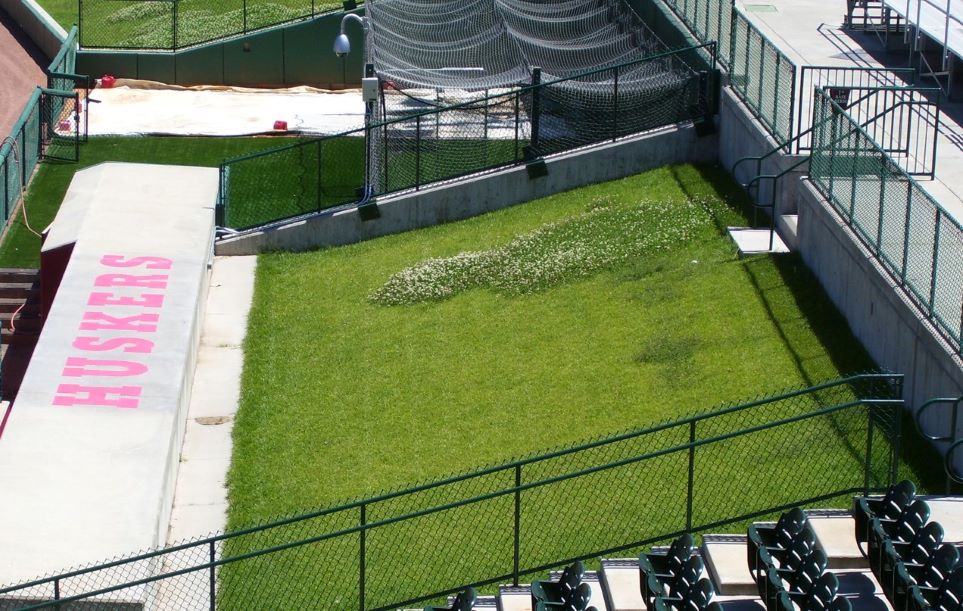

The point in time where it becomes especially useful is when lots of activities, chores and needed operations are vying for the forefront of your mind, and it is difficult to remember exactly where those patches of white clover are located (Figure 6). A simple weed map with notes, circles and various colors of ink provides invaluable information.

Contact all suppliers

Considering supply chain shortfalls, shipping issues and price increases, an honest discussion with your current and future vendors could yield positive results. Even though it may seem like the leverage in the relationship has shifted from buyer to seller, at the end of the day, a sales representative still has to convince the sports field manager to buy from them and not from someone else. Knowing the field’s needs in terms of irrigation supplies, fertilizers, pest control products, ornamental maintenance tools, striping equipment, mowers and other repair tools – and having them in mind during the discussion – will provide a foundation. Being open to new products and techniques will pay off as well.

Bradley R. Jakubowski is a turfgrass and irrigation instructor with Penn State University. He is a certified irrigation technician with the Irrigation Association and is an author and presenter covering multiple management areas within the turfgrass industry. He focuses his time on teaching best irrigation practices and troubleshooting, weather-based management decisions, soils and plant nutrition.

John C. Fech is a horticulturist with the University of Nebraska-Lincoln and certified arborist with the International Society of Arboriculture. The author of two books and more than 400 popular and trade journal articles, he focuses his time on teaching effective landscape maintenance techniques, water conservation, diagnosing turf and ornamental problems, and encouraging effective bilingual communication in the green industry.

All photos provided by the authors.