In an effort to keep the pulse of the industry, SportsField Management recently reached out to industry professionals for their insights regarding current trends in the industry. In Part 1 of this series, we covered overall challenges being faced and outlook for the industry. Part 2 of our coverage features expert insight regarding fertilizer trends, the benefits of using controlled-release fertilizer, and other related issues such as labor, and freight/distribution.

Between irrigation repairs, scheduling, mowing, painting, custodial, overseeding and planning, a sports field manager’s plate is pretty full. Add in fertility, and that plate can be overflowing as changing weather, scheduling challenges, and labor shortages crop up. Many sports field managers across the country are adopting fertility programs that contain polymer-coated urea that delivers nitrogen over extended periods of time. This technology allows for fewer fertility applications and saves managers application labor, freight, storage and nutrient loss, while delivering equal or better results to keep fields safe and playable while looking and performing at their best.

Labor is one of the largest issues facing the green industry today. “Finding employees is still a significant issue,” according to the 2020 Green Industry Benchmark Report, and throughout the pandemic, the challenge of finding reliable help has been amplified. Labor is not a new problem; it is an ongoing problem.

With the higher cycling-rate, high tissue sufficiency levels, and potential for loss to the soil and air, N and K are the most often needed and applied nutrients to turfgrass (Mills and Jones, 1996). Polymer-coated urea technology allows sports field managers to make fertility applications that provide 2, 3, 4, and 6-months or more of nutrition. With nitrogen protected from loss, sports field managers can focus on fine-tuning their levels of secondary and micronutrients in the areas where they are less than sufficient.

Not only does utilizing controlled-release urea provide labor savings when applying fertilizer, it also saves customers in freight expenses. Sports field managers have the option to apply as little as one application for season-long fertility. As fertility applications are reduced, so does the need to freight and store fertilizer during the growing season.

– Chris Bluemke and Nate Mezera, EC Grow

Sports field managers are faced with escalating challenges today as the industry begins to recover from the limited activity on field surfaces experienced during the pandemic.

The ‘new normal’ confronting the sports field manager not only involves trying to restaff, but to contend with increased costs of materials that exceed the former budget allowances.

Today, the cost of fertilizer is significantly higher than it was 18 months ago, and there is no indication of a reversal in the escalation of costs.

The factors driving these increases are related to what is being referred to as ‘supply chain issues.’ These issues include raw material availability, increased production costs, labor shortages and transportation costs.

This would be a good time for the sports field manger to visit with his or her fertilizer salesperson and discuss the merits of incorporating controlled release fertilizers (CRF) into the field management program to save costs.

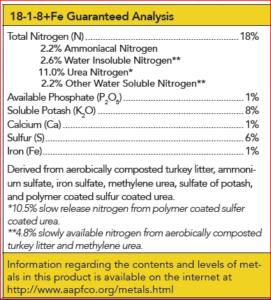

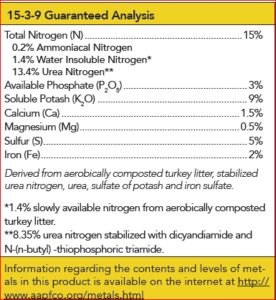

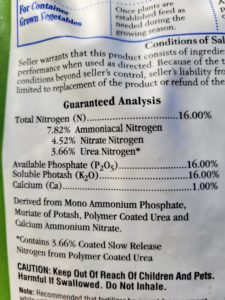

CRF, SRN (slow-release nitrogen), WIN (water insoluble nitrogen) and ‘stabilized nitrogen’ are commonly advertised as a percentage of the fertilizer NP&K, which suggest the length of time the fertilizer will last. The components in the specific fertilizer that provide the basis for the use of the SRN can be found on the fertilizer label and most specifications, and is called the Guaranteed Analysis.

The fertilizer salesperson can explain the differences between polymer coated urea, methylene urea, stabilized nitrogen, etc., to help determine which product will be appropriate for the sports field manager. Each different component has different methods of release that are influenced by the environment, primarily moisture and temperature. In addition, the Guaranteed Analysis will show how much of the fertilizer can be expected to be available quickly as well.

Knowing which fertilizer is suitable for the manager’s grass type, season and growth requirements, it is time to review the potential cost benefits of the material.

In the example at right, the 18-1-8 and 15-3-9 are promoted at being 65% SRN. The 18-1-8 is suggested to last 12 to 16 weeks, while the 15-3-9 is suggested to last 10 to 12 weeks. Compare this to a fertilizer with 23% SRN that is suggested to last 9 weeks. Using a hypothetical cost of $40.00 per bag for the 18-1-8, $35.00 per bag for the 15-3-9 and $25.00 per bag of a 16-16-16 the cost per day respectively is:

18-1-8 – $1.79 per day – 112 days

15-3-9 – $2.50 per day – 84 days

16-16-16 – $2.18 per day – 63 days

The cost per day doesn’t fully explain the total cost, as the number of applications (labor), delivery (transportation) environment (weather) and mechanical degradation of the fertilizer all impact the total cost.

“By combining the synthetic CRF’s with the slow-release N, you get the best of both worlds, longer release on the nutrition, as well as soil conditioning for the fields with each application,” said Russell Riley, European and Middle East Manager for Sustane Natural Fertilizers. “Also, applying an organic with aeration will help to rebuild fields in poor shape, without having to totally renovate the entire field, saving money in the long run.”

“I always shout out the benefit of organics/humic first before mentioning the CRF on all our natural blend analysis,” said Henry Ng, Sustane’s manager for Asia. “It helps to optimize microbial population in return helping a more consistent release and utilization of nutrients in CRF, at the same time sustaining or improving soil health.”

The differences in cost can also be offset by the physical makeup of the fertilizers. Is it a homogenous fertilizer particle, two-particle blend, or several particle blend? Is the fertilizer available only in bags or is it available in 1,000- or 2,000-pound totes? What is the particle size?

Reviewing your fertilizing options can, and should, be considered as we move forward to better turfgrass tomorrow.

– Greg Naffz, Sustane Natural Fertilizer, Inc.