By Chrissie A. Segars, Ph.D. and Charles Fontanier, Ph.D.

Whether it is your first day on the job or you are a seasoned veteran, knowing your irrigation system is vital for successful management of your sports fields. Each field is a unique organism that requires proper maintenance practices in order to create a safe playing surface for athletes. This article provides basic steps on conducting irrigation audits and how to use those results to make your system more efficient.

An efficient irrigation system not only gives us less headaches, it leads to reduced water use/wastage, less hand watering, less need for inputs like fertilizer or chemicals, and less budgetary concerns. An efficient irrigation system has four components: 1. The correct hardware, 2. Proper installation, 3. Long-term maintenance, 4. Management of the system.

The audit

An irrigation audit is a method of inspecting and measuring the amount of water applied and the efficiency with which the sprinklers are working together to apply the water within an individual zone or test area. When the audit is done, the results are compiled to be used in combination with your observations to facilitate irrigation management. Before conducting an audit, we should fix the obvious. Problems like broken sprinkler heads, mismatched or clogged nozzles, leaky heads or pipe, and heads that are not level will cause inaccurate audit results. These issues should be no-brainers and are easily identified with a simple visual check. A good field manager will make a habit of visually inspecting and auditing their irrigation system regularly.

Steps for the irrigation audit:

- Site evaluation

- Irrigation system tune-up

- Catch can test

- Calculations

- Report findings

- Make decisions

For the purpose of this article, we will focus on the catch can test and a few of the most common calculations. The key outcomes of a catch can test are: 1. Average precipitation rate, 2. Distribution uniformity coefficient, and 3. Runtime.

Key questions before starting the test

Q: How many cans do I need?

A: At least 24 uniform catch cans per zone.

Q: How should the cups be spaced?

A: Cups should be spaced within 2 to 3 feet of corner head and every one-third of the distance between the heads (or one-quarter for >40-foot spacing).

Q: How long do I need to run the zone?

A: Run zone under “normal” operating conditions (especially pressure) in 5-mph-or-less wind. The amount of water should be 1.5 times the throat area of the cup. Spray heads: 5- to 10-minute runtime. Rotors: 10- to 20-minute runtime (at least five full rotations for large rotors).

Q: Do I need to test every zone?

A: Ideally, yes, every zone should be tested to promote consistency. In cases where the design of two zones is identical, an audit on one zone can be applied to the similar zone (termed “linking”).

Once your audit is done, it is time to do some math, and take a look at some examples of calculations done from an audit. This example is based on catch cans that measure in inches. ther catch cans might measure in mL or other volume. In these cases, an additional conversion may be required. (Note: All equation information was adapted from STMA’s resource, “Conducting an Irrigation Audit.”)

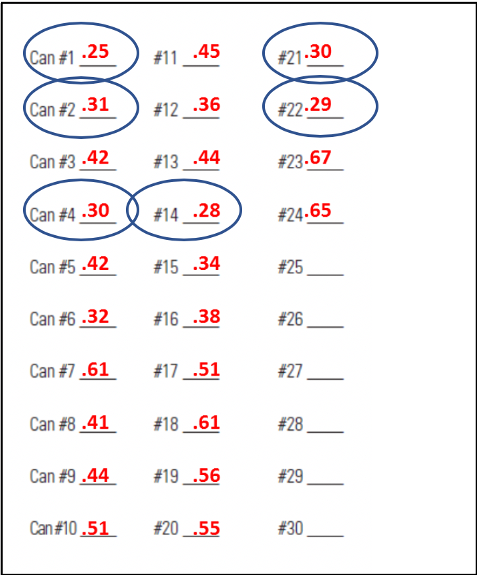

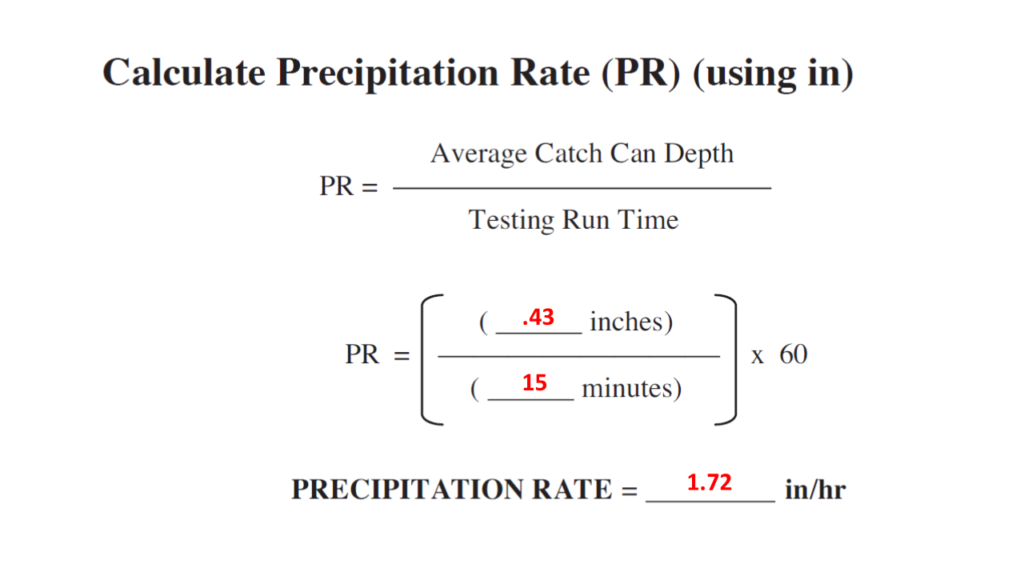

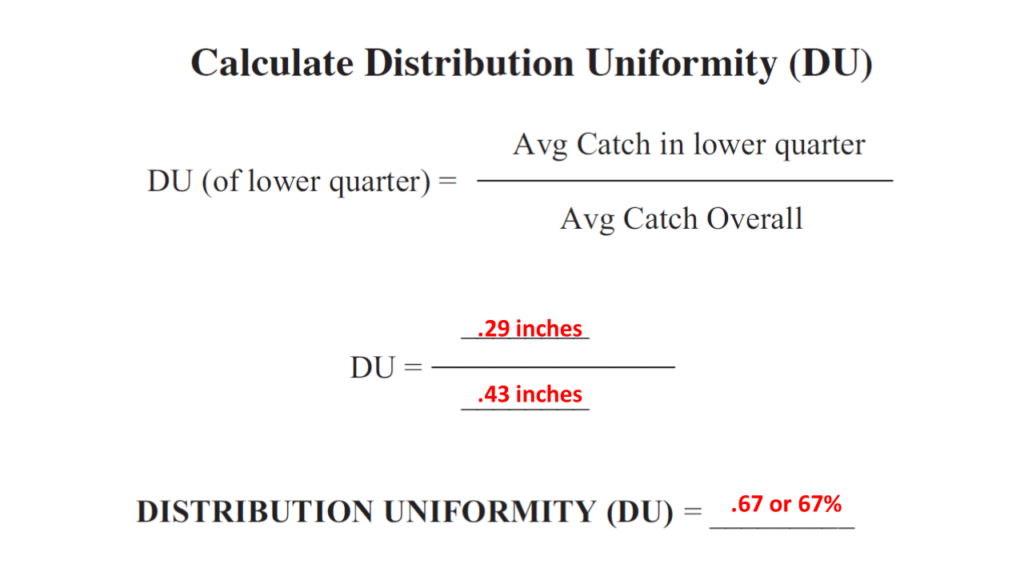

Figure 1 shows an example from an irrigation audit using 24 catch cans. This information is used to calculate the system Precipitation Rate (Figure 2) and the Distribution Uniformity (DULQ) (Figure 3). Precipitation rate is simply calculated by taking the average of the catch can depth, dividing by the test runtime, then multiplying by 60. This will give you the system output rate per hour. The most common method for calculating DULQuses the Lower Quarter of catch can measurements to determine the average for the driest part of a zone. For a test using 24 catch cans, that means you will need to determine the average of the driest six cups. For this example, we took the average of can #1, 2, 4, 14, 21, and 22 (Figure 1). After plugging the data into the formula in Figure 3, we now know this zone has a DULQof 67 percent, which would be considered acceptable but still leaving room for improvement. A DULQof 70 percent is considered ideal. Of course, no irrigation system will be 100 percent, but adjustments can be made, and the system re-tested to obtain the best performance for that zone.

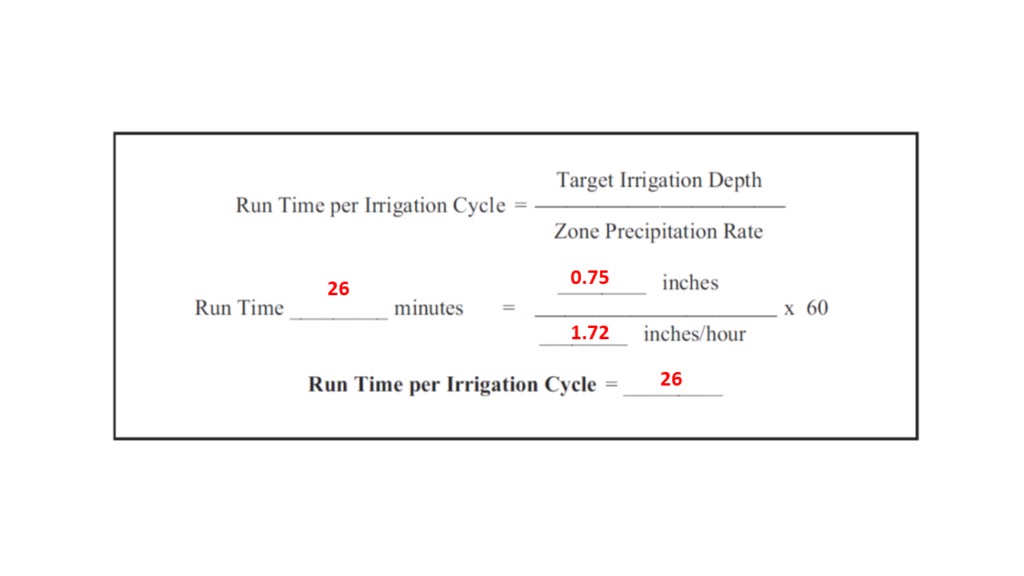

Calculating the DULQcan be valuable simply for scouting problems in the system, but can also be used directly when scheduling irrigation. For example, let’s assume we would like to apply 0.5 inches of water to our field. If the distribution uniformity is 67 percent, that means not all of our field will get the amount of water we want. To correct this, we would divide our target irrigation amount by the uniformity (0.5 inches/0.67 inches = 0.75 inches). In this case, we would need to apply approximately 0.75 inches of water to get our desired amount of 0.5 inches to all parts of the field. Now, using the schedule multiplier, along with the precipitation rate, we can determine our runtime (Figure 4).

Troubleshooting

A critical factor of keeping an efficient irrigation system is pressure management. Low pressure can cause problems including lack of head to head coverage, which leads to uniformity issues, irrigation heads may not pop up from the ground, and ultimately a decline of plant health. High pressure can also cause a loss of irrigation efficiency. If pressure is high, it will lead to fine water droplets that will have increased evaporation, are easily carried away by wind, and ultimately a decline in uniformity and plant health. In severe cases, high pressure may lead to blowouts and broken parts of your irrigation system.

If you suspect a pressure issue, the first step is to measure the water pressure from one of the heads. Although this may not show pressure losses within the system, it can be a general guide to how much pressure is being carried to the system. When checking system pressure, don’t overlook the obvious. Make sure the isolation valve is open, check your backflow device to ensure it is not partially closed, if you have a pressure regulator, make sure it is properly adjusted, and look for debris that may be clogging heads, filters or valves. If you have checked these simple fixes, finding bigger problems may be tough to address on your own. Consulting an irrigation professional may be the next step if bigger problems arise.

No irrigation system is 100-percent efficient. All systems will require periodic maintenance, but annual auditing will help to avoid major issues. When conducting an audit, use your eyes to observe problems, and the results to confirm performance of your system. Make adjustments, then repeat the audit if necessary. You can then use best management practices to conserve water and maintain player safety. As always, please use your network and friends to your advantage. Do not be afraid to ask questions, and always continue learning.

Chrissie A. Segars, Ph.D., is assistant professor and extension turfgrass specialist at Texas A&M AgriLife Extension, Dallas, Texas.

Charles Fontanier, Ph.D., is assistant professor of turfgrass, Department of Horticulture and Landscape Architecture, Oklahoma State University, Stillwater, Okla.

References

• Hunter Industries Inc. 2012. Irrigation system design workbook.

• Irrigation Association. 2009. Irrigation audit guidelines. CLIA-CGIA.

• Moore, K., and J.Q. Moss. 2019. Managing pressure in the home irrigation system. OCES Factsheet HLA-6617.

• Sports Turf Managers Association. Conducting an irrigation audit.

Irrigation audit kit resources

Irrigation audit kits can be bought from irrigation companies and many universities. Check with your local distributor or contact an agricultural university for more information.

Helpful Terms

Catch Can: Typically a conical-shaped apparatus used to catch irrigation water from sprinklers. Any short or straight-sided container can work.

Distribution uniformity: A measure of how uniformly water is being applied to the plants in a measured area.

Lower Quarter Distribution Uniformity (DULQ): Average water applied in 25 percent of driest areas divided by the average water applied over the total area.

Precipitation rate: Rate of water applied to the turf, usually in units of inches per hour.

Pressure: A force unit per area in pounds per square inch (psi).

Scheduling multiplier: Equation used to adjust runtime based on distribution uniformity.