By John Sorochan, Ph.D. and Kyley Dickson, Ph.D.

Athletic fields require regular maintenance whether the surfaces are natural or synthetic. One under-appreciated and challenging aspect for managing athletic fields is that both systems change as a season progresses. One of the best ways to reduce player injuries and increase player performance is to have a consistent playing surface that is kept within acceptable ranges for athlete safety. Without regularly testing fields, it is hard to determine variances in playing surface consistency as use/wear increases. Knowing how a field is changing throughout the year can help field managers make data-driven decisions to optimize the performance of the playing surface and help keep athletes safe. Keeping records of different field conditions across years and within seasons can help a field manager visualize what is going on across the surface. Although testing takes time and can be expensive, the knowledge gained by field managers can help extend the quality and longevity of a field, can improve player performance while protecting player health, and can mitigate risk.

One of the main benefits of testing a field is that it indicates consistency and characteristics of a field’s impact on athletes. Tests that are conducted provide clues to the safety and performance of a field, and help identify which maintenance practices are needed. Although there are different testing criteria for natural and synthetic surfaces, knowing what is needed for a synthetic field is critical. When determining what tests to conduct, knowing what sport or sports are played on the field is essential. Another critical question is what is the budget and time available for testing. This information will help determine what tests would provide the most beneficial information for a surface. To start, some basic tests need to be established for field managers as a base. Just like a doctor checks for blood pressure, weight, and pulse at most visits, having a baseline tests for synthetic turf athletic fields provides that quick look into the field’s health.

The University of Tennessee Center for Athletic Field Safety (UTCAFS) has a suggested basic kit for synthetic fields. The basic kit for a synthetic surface recommends an infill depth gauge, surface temperature measuring device, and some type of rotational traction device. The costs for synthetic turf kits range from $850 to $1,000. All kit estimates are from price researching different suppliers’ websites and then totaling the cost. The purpose of this article is not to promote one specific brand of testing equipment, as there are a variety of products available. The key thing is to be consistent with the testing device being the same each time, if possible.

All testing done is a snapshot of that field at that particular time – the same test could be conducted the following week with different results. That is why taking multiple readings in a year will give a more detailed picture of what is happening. As a human doctor might want to track blood pressure or some bloodwork several times throughout the year to determine what could be impacting the health of a patient, tracking field results is just as important. The other key in getting a good snapshot is testing for the variables that have the greatest impact. For synthetic turf, infill depth can be just as important as soil moisture is to a natural grass system. The infill depth is often taken for granted on many synthetic fields. As seasons progress across the lifespan of a synthetic turf field, infill will be moved around and areas of concern will be formed on the field that are lower or higher than adjacent areas. Variances in infill depth have been found to impact surface hardness, surface temperature, and also rotational traction (Center for Athletic Field Safety Reports). Measuring infill depth uses a metal rod/rods that are inserted until the backing is contacted by the rod/rods, the top of the infill is determined, and the distance the rod/rods are inserted into the surface is the infill depth (Figure 1). The results will let the field manager know if additional infill is needed, or if the infill simply needs to be redistributed from areas that are too high to areas that are too low. The goal is keeping the infill depth as close to manufacturer’s recommendation as possible.

Surface temperature is another important variable to turf health, as well as field and player performance. Synthetic turfs have temperatures that can be much higher than natural grass fields during full sun hot conditions (Lim and Walker, 2009; Thoms et al., 2016). As heat increases to temperatures as high as 175 degrees Fahrenheit (Knoxville, TN, August 12, 2019, at 3 p.m.) on synthetic turf, it has a detrimental impact on athletes, decreasing performance and increasing the need for breaks and rehydration (Charalambous et al., 2016). Surface temperatures can be taken with a variety of tools, but a handheld temperature gun (available at most automotive and do-it-yourself supply stores) is an inexpensive, fast and easy device for gauging the surface temperatures of a field. Although little can be done to reduce synthetic turf temperature after a system is installed, educating field stakeholders of potential heat concerns is one potential plan of action.

Rotational traction is an additional tool that is very useful for synthetic surfaces. These testing devices give more of a performance and safety standpoint for the athletes on the field (Figure 2). Trying to keep a field consistent for rotational traction is helpful in providing consistent footing and potentially safer playing surfaces. Rotational traction has been associated with both lower extremity injuries and grass health (Orchard et al., 1999; Stier et al., 1999). The smaller portable devices are relatively easy to use and quick.

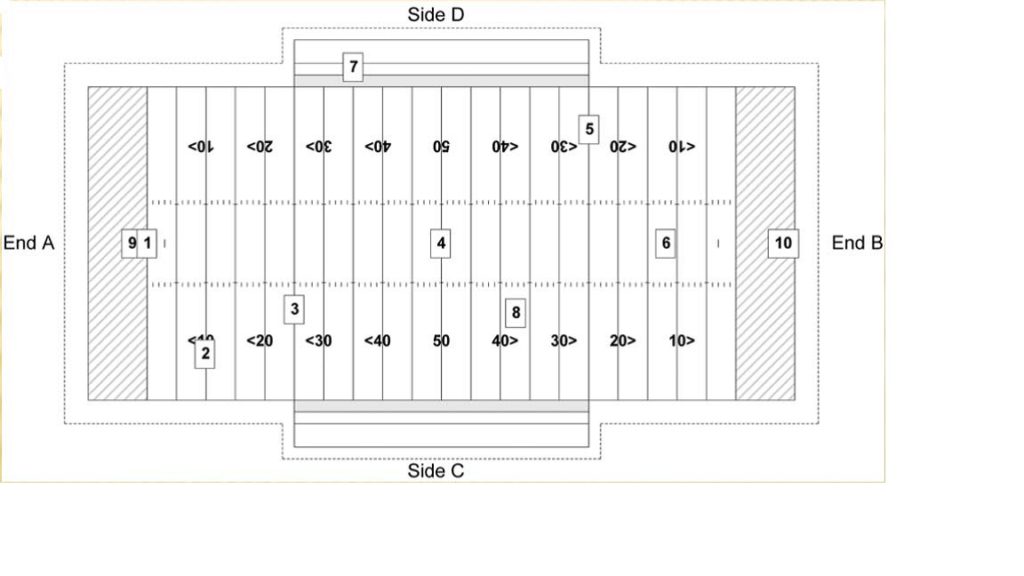

The tests described above are just the basics. There are many more tests available if budget and time permits. When considering what sport/sports are played on the field, additional tests can be beneficial. In football, knowing surface hardness and rotational traction are of greater importance than ball-to-surface interaction questions. In soccer, FIFA has requirements about ball roll and ball rebound that take place on a field. Field testing locations of a field are also be important for choosing where to test (Figure 3). Minimal recommendations are to test the same 8 to 12 spots on a field each time while testing additional areas that may also be of concern. The more locations that can be tested on a field provides greater detail of the surface. Testing the same spot across time and recording the results in a spreadsheet or other mapping platform will help the field manager interpret the findings in a meaningful way. These records will tell you how it is changing each time testing is completed. Testing after traffic events could indicate the need for infill maintenance or decompaction. Or, if a coach complains that the field is too soft/hard, numbers can be provided to show a quantitative measurement. Comparing multiple fields in a sports complex can show how different fields may vary from each other (and where) due to use, construction, infill selection and depth, shockpads, and other factors.

Although there are more tests available, these basic tests suggested can potentially increase the performance and safety of an athletic field, and can be completed quickly with minimal expense. These quick data snapshots throughout a season would take less than an hour to complete per field, and would provide extremely useful information for the field manager. When you put the snapshots together for the entire year, you get a pretty clear picture of the changes that occur throughout the season. Ultimately, this data will also aid in maintenance decisions needed to provide a consistent playing surface. When it comes to field testing, start with the basics and work out from there.

John Sorochan, Ph.D., is a professor of turfgrass science at the University of Tennessee and director of the University of Tennessee Center for Athletic Field Safety in Knoxville.

Kyley Dickson, Ph.D., is a turf researcher at the University of Tennessee.

Work Cited

Charalambous, L., und Wilkau, H.C.V.L., Potthast, W. and Irwin, G., 2016. The effects of artificial surface temperature on mechanical properties and player kinematics during landing and acceleration. Journal of sport and health science, 5(3), pp.355-360.

Lim, L., and Walker, R., 2009. An assessment of chemical leaching, released to the air and temperature at crumb-rubber infilled synthetic turf fields. New York State Dept. of Health. pp. 1-140

Orchard, J., H. Seward, J. McGivern, and S. Hood. 1999. Rainfall evaporation and

the risk of non-contact anterior cruciate ligament injury in the Australian

Football League. Med. J. Aust. 170:304–306.

Stier, J. C., J. N. Rogers, J. R. Crum, and P. E. Rieke. 1999. Flurprimidol effects on Kentucky bluegrass under reduced irradiance. Crop Sci. 39:1423-1430.

Thoms, A.W.; Brosnan, J.T.; Zidek, J.M.; Sorochan, J.C. Models for Predicting Surface Temperatures on Synthetic Turf Playing Surfaces. Procedia Eng. 2014, 72, 895–900, doi:10.1016/j.proeng.2014.06.153.