Traditionally wired and 2-wire are both types of irrigation systems. However, they are fundamentally very different types of technology.

A traditional irrigation system involves a controller sending voltage down a wire path, which activates a solenoid, in turn opening a valve allowing water to flow to the sprinkler heads. Decoder, or 2-wire, systems involve a different kind of architecture, which I will outline later in this article. Both types of systems possess inherent qualities that can make them better or worse for a specific application. Therefore, understanding the application will help you determine which type of system would be a better fit.

Traditional irrigation systems require one dedicated wire for each zone valve, plus a common wire linking all of the valves. This can add up to a lot of linear feet in copper wire. Most decoder systems only have one 2-wire path linking all of the devices (valves, sensors, pump relays, etc.). Therefore, the size of the irrigation system can help determine which type of technology should be installed. Once a system gets more than 30 to 35 zones, it becomes less expensive to install a 2-wire system.

While cost will almost always be a consideration, another factor that can give traditional systems an advantage is the relative simplicity. Since the wiring architecture is very basic, almost any irrigation contractor knows how to install and troubleshoot them. Whereas a 2-wire system forces us to choose from a smaller pool of contractors. Oftentimes, this will drive up the cost of the system.

One distinct advantage to 2-wire technology is its expandability. If a new section of irrigation needs to be added to an existing 2-wire system, the path can be tapped into and new irrigation can be added. Also, due to the fact that most 2-wire controllers can handle hundreds of zones, adding zones to an existing system is rarely an issue. When a traditionally wired system needs to be expanded, new wires will often need to be run back to the controller, making it cost prohibitive.

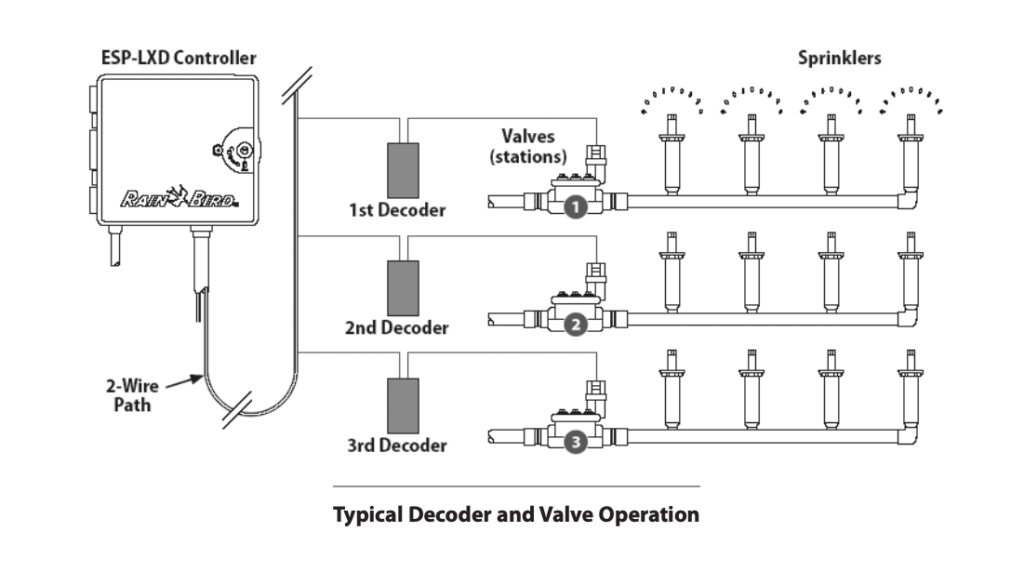

A 2-wire controller is always sending voltage (usually 24-30 volts AC) down the 2-wire path in order to communicate with the components in the irrigation system. In order for the controller to talk to each device, there needs to be a decoder between the 2-wire path and its respective device. Each decoder has a unique address that acts as a telephone number. So, when the controller wants to open a valve, it dials up the specific decoder and tells it to send voltage to the solenoid, opening the valve.

2-wire technology has been around for many years in the golf industry, but is only recently gaining traction in the residential/commercial market. This increase in use is being driven by a few factors: the ever-increasing cost of copper wire, the decreasing cost of the technology, and the fact that more contractors are becoming familiar with it. Perhaps the biggest factor holding it back has been the apprehension of contractors who are unfamiliar with the technology and how to install it. As more contractors learn about the advantages of 2-wire, and become more familiar with installation and troubleshooting, the technology is being embraced.

One of the biggest advantages with this technology is the sharp increase in diagnostic ability. In a traditional system, the controller is simply sending voltage down the wire path. In a decoder system, the wire path is meant for communication. This enables the controller to use built-in diagnostics to check out the health of the system, and can signal an alarm if there are any issues with the decoders, solenoids or the wire path. Since the solenoids are after the decoders in the wiring architecture, traditional troubleshooting techniques (voltage and resistance) will not work. Instead, a clamp meter capable of reading 1.0 milliamps must be used to read the amperage draw from the downstream decoders. An accurate as-built is always very helpful when troubleshooting 2-wire, but a good clamp meter is essential.

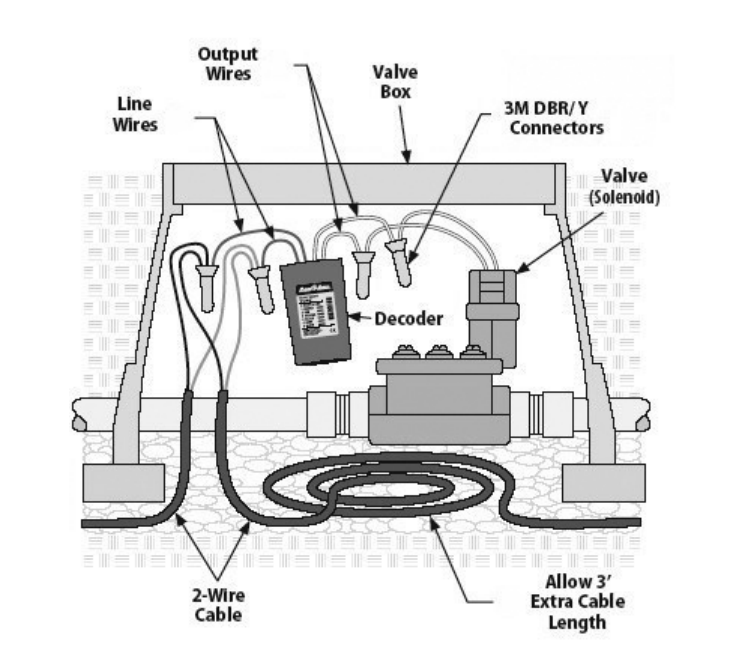

Since 2-wire systems are always sending current down the path, any bit of exposed copper will inevitably corrode. Therefore, proper waterproof wire splices are critical. At least 90 percent of 2-wire issues are found at the splices, which should always be in a valve box and never be buried in the soil. Another essential component required to ensure the long-term health of the system is proper grounding. Decoder systems are very susceptible to lightning strikes. Therefore, grounding rods or plates should be buried every 500 feet or every 8 to 15 decoders, depending on the manufacturer’s requirements. The general rule of thumb is to make sure the resistance between the wire path and the ground is less than 10 ohms. This will give the lightning a path to the ground, minimizing the potential damage to the system. Most manufacturers recommend grounding the controller as well.

As 2-wire technology continues to become less cost-prohibitive, the ratio of systems being installed will continue to shift toward decoder-based systems. Many believe that traditionally wired systems will eventually become a thing of the past. Regardless of what happens, we can always expect that new technologies will continue to influence how our respective industries will evolve. Embracing new technologies will be critical in ensuring that we are always getting better, not only as individual professionals, but also as a society.

Editor’s Note: This article was provided by Rain Bird, and was written by Heath Traver, CID, CIC, CLIA. Traver is a specification manager for Rain Bird in the Northeast United States, and is licensed to practice irrigation in the state of New Jersey. He can be reached via e-mail at htraver@rainbird.com.