By Ryan Adams

The most important step in site-specific management is the identification of your high traffic areas. Proper diagnosis of the cause of the problem, whether due to over usage, compaction, poor drainage, weed encroachment or various other factors will provide a better return on investment and create increased safety and longevity of all fields.

A majority of wear and compaction related issues originate in high traffic areas. In general, high traffic areas of a football and soccer field are both around 17,000 sq. ft., assuming you’re managing a high school football field with 53 ft. wide hash marks. Soccer dimensions, including the center circle as well as the goalmouths also equate to approximately 17,000 sq. ft. It is important to assess your resources on high traffic areas for each of your fields; however, in between hash marks is not always the biggest concern. All fields present different challenges and require strategies specific to the site and field. The total number of games and practices, as well as the frequency and age of users/athletes can influence the amount of the damage from a single event or weekend tournament. All of these things need to be accounted for when determining resources. For the purpose of this article, we will examine cost analysis strategies for 17,000 sq. ft. or 3.5 times smaller than the entire area in and around the field.

Topdressing. The biggest costs associated with topdressing are the fees required to physically move material to your facility. The standard cost for freight is about $4.03/mile + $0.24 cents per fuel or $4.27 per mile. Transporting a truckload of sand topdressing 100 miles would cost $427 dollars. The freight costs exceed the price of sand ($337) if using $13.50/ton Class 2 USGA sports turf sand. Current estimate of sand costs: USGA sports turf sand 90/10: $31.40 per ton; Class 2 USGA sports turf sand: $13.50 per ton; Mason sand: $12 per ton.

Topdressing high traffic areas to a 1/4 in. of sand would require 1.12 tons/1000sq. ft. or 19.04 tons/17,000 sq. ft. In comparison, topdressing the entire field at 1/8 in. would need 0.56 tons/1000 sq. ft. or 33 tons/60,000 sq. ft. With the expense of transportation and difficulty in finding high-quality sand, it is important to consider whether the entire field is worthy of an application. In many cases, an application to the high traffic area is sufficient for field quality, aesthetics and longevity.

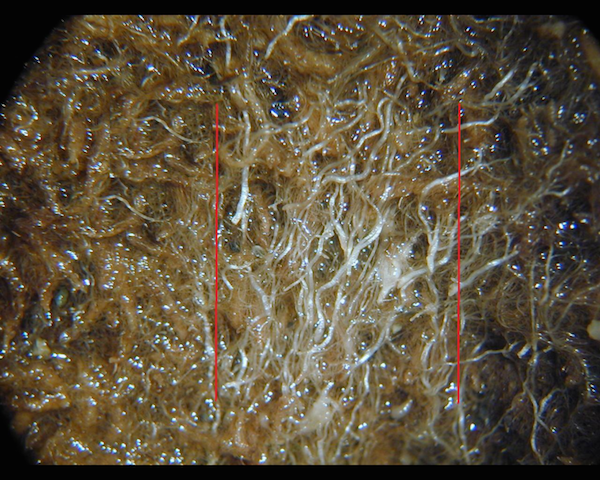

Aerification. The best way to combat excessive field use is with an extensive aerification program. Aerification reduces compaction and reintroduces oxygen, water and nutrients into the rootzone. It can also be beneficial in combination with a sand topdressing program to improve the internal drainage of a field, reduce thatch, improve fertilizer uptake efficiency, as well as providing a uniform surface that is safer for playing sports. Consistent aerification can also provide an exceptional environment for new seedling growth and development. Furthermore, aerification encourages deep rooting as seen in the figure.

Native soil fields are more prone to compaction than a sand-based system because of the higher clay content. Clays, especially when wet, are highly prone to compaction. Regardless of the rootzone constituents, using hollow-tine or core aeration is absolutely necessary in the battle to prevent excessive field wear and soil compaction. All fields should be aerated at least two times per year, regardless of budget. On high-use sports fields, it is not uncommon to aerate 4–8 times per year. I am a huge fan of the “beat it up” methodology; anytime the field starts to look great in the off-season or downtime, it is time to aerify, verticut, or topdress. Prepare the field for battle during the off-season, so it can take the wear during the season! For fall sports, you should never allow your field to peak in May, June, or July; you want it to be perfect for that first game which usually arrives in Iowa in mid-August.

As mentioned previously, a great time to seed and build a seed bank is following aerification. Late summer or early fall is the best time to aerify cool-season athletic fields, however, anytime works as long as environmental stresses are low and a period of downtime (>2-3 weeks) exists before the next field activity.

Each year, a majority of the sport turf industry is shooting for 25-35% surface disruption through aerification. It is important to remember that pulling a soil core using 3/4 in. hollow tines can double the area of the field that is impacted, in comparison to a 1/2 in. tine. Selection of the right tines based on future schedule can make the difference in meeting this lofty goal.

Using the high traffic area defined above, 17,000 sq. ft.; 0.5 in. aerification holes to a depth of 3 in. on 3 in. core spacing requires 1.41 tons of sand/1000 sq. ft. to backfill holes and surface apply 1/4 in. Therefore, a truckload of sand would cover the 23.35 tons needed for the high traffic area.

Pitchfork challenge

I challenge you to go out once a week and open up the exposed soil (soccer goalmouths, field goal kicking areas and baseball outfields) with a pitchfork. To cover the 5-10 sq. ft. area, it takes 5 minutes a week and within a few weeks, you will see a huge improvement and difference in these highly compacted areas. Once exposed, add about 45g/10sq. ft. of seed (10 lbs./1000 sq. ft.). A 50lb. bag of 50-50 Kentucky bluegrass/perennial ryegrass seed costs about $2.25 per pound or $112. A single bag can seed that 10 sq. ft. area more than 500 times and would cost you $0.22 cents per application. The addition of half-pound rate (5g per 10 sq. ft.) of nitrogen using urea (46-0-0) will increase growth following germination. The current cost of urea is about $16.00 per 50lb. Ultimately, a single urea application at a half pound of nitrogen costs $0.0032 per application. That is correct, not even a cent per application? Means it’s free right? A complete fertilizer or starter fertilizer containing phosphorus can also be used to increase germination.

Adding topdressing to a depth of 1/4 in. needs about 1.12 tons/1000 sq. ft. assuming sand weighs 1.45 ton/cu. yd. and there is 100% efficiency on your hand-made aerification holes. A 10 sq. ft. area would need 0.01 tons or 22.4 lbs. of sand. Given that 1 gallon of beach sand is approximately 12.76 lbs., you would need 2 gallons or approximately half a 5-gallon bucket. The topdressing can also be used to level the playing field and fix any divots or depressions that have formed.

Seeding/Fertility. Using high seeding rates for athletic fields allows for faster ground coverage and provides better competition with weeds, especially summer annuals, such as crabgrass. Higher than normal seeding rates of Kentucky bluegrass applied at 3–4 lbs./1,000 sq. ft., and perennial ryegrass at 10–15 lbs./1,000 sq. ft. provides faster coverage. However, it is important to slightly increase the fertilizer rate with these higher seeding rates. I commonly use the analogy of Thanksgiving Dinner, if a 12lb turkey feeds your family of five, would it feed everyone comfortably if you increase your family to 10? The answer is NO! You would need a larger turkey to feed the additional people; the same can be said when increasing the seeding rate.

Applying seed with a drill seeder or drop spreader after core aerification is preferred. Grass crowns that are deeper in the soil are more protected than those on top of the soil, which can be damaged by high traffic and desiccation. In addition, combining different seeding techniques over the course of a year is optimal to begin creating vertical layer establishment (seed bank column in soil profile). Broadcast seed and topdressing, pre-germinated, broadcast and spike, dragging field, verticutting, surface application cleated in by players all increase seed germination and provide multiple layering of seed at different depths. The ultimate goal is to “never be bare.” Once the soil is exposed, it will be a difficult to re-establish grass in these areas.

A goal for grass-bare areas is for seeding to occur within 24 hours of discovery. Instead of waiting to seed and re-establish the grass once or twice per year, use multiple seeding events; say 6–10 times during the year. There is no bad time to seed; as some seedlings die, others will survive. Seedlings that survive are the building blocks for the beginning of next season. It commonly takes 12-18 months to develop a beneficial mat after seeding. Seed grass whenever the soil is exposed or loss of turf cover due to heavy traffic is anticipated. If there is any doubt that the field may not withstand the traffic from the next game or practice, the seeding should have happened last week.

Many athletic fields currently use site-specific seeding techniques and those who do often fall into the upper tier of field quality. A blend of high quality Kentucky bluegrass costs about $3.50 per pound while a 50-50 blue/rye mixture is about $2.25 per pound. Seeding the high traffic area (17,000 sq. ft.) alone at 4lbs. of KB/1000 sq. feet would cost $230/application, while a 50-50 mixture would require 165.60 lbs. of seed or $372/application at 10lbs. /1000sq. ft. rate.

In comparison, a KB application to the entire field would need 240lbs/application and cost roughly $840. Seeding the high traffic area four times would cost $920. So next time you overseed, consider whether the entire area needs an application, or whether the high traffic area is the priority.

Communication as means to traffic control

It is very crucial to have communication among the administrator, coach, band director, and field manager. Accepting your role as a user of the field is the first step in communication. Below, I will highlight several of the different roles and their influence on overall field quality.

The role of the big bad band. The band director needs to realize his influence on field safety, playability and longevity. A separate practice field should be painted on another grass area, or in a parking lot specifically for the band. The area should be situated so that the practice can be viewed from above, as if you were in the bleachers. Band practice on the game field should be limited to once per week, and only when the soil is dry enough to resist compaction. Just like the football team, the band should never practice on the game field after a substantial rainfall event. Their repetitive movements can cause significant compaction and wear, resulting in a decrease in turf quality.

The coach. The coach must take an active interest in scheduling practice activities and preventing excessive turf wear. The coach and the grounds manager can work together to develop improved grass areas specifically for drills that are conducted on/off the game fields. Field rotations should occur monthly. If you have the ability to change field orientations, and rotating heavy traffic areas, DO IT! Spend time talking with the coach and explaining that this approach works best for them. A majority of practice fields are still poorly used because of the concentration of drills on certain areas of the field. Commonly, the side of the field nearest to the locker room, parking lot, or some other point of interest is used more often than the far end. Encourage the coaches to use both halves of the field to reduce wear and allow for turf recovery.

Field manager. In most situations, the field manager should realize that he is caring for a multi-use facility rather than a single field. He needs to account for additional labor, equipment, and resources to combat all school functions. Graduation, classes, track meets, concerts, and in some cases soccer games will use a portion of the field or sidelines throughout the season. It is the role of the field manager to be the biggest advocate of using practice fields if and when possible. If practice fields are available, require use and leave game fields for games only. The biggest detriment to poor playing conditions is excess traffic and compaction. Resources should be allocated so that you have at least one “showcase field.” This lets your boss and the public know that you are capable of producing high-quality turf when given the proper schedule, tools, and budget. This also helps with job security and reputation. Even if resources are limited, don’t spread them out so that all of your fields are average-to-poor quality, or your reputation as a grounds manager may be perceived as average-to-poor. One of the most important things a field manager can do is documentation. Always write down maintenance schedules, and use these to justify how an increase in resources will improve the rest of the fields that are in average-to-poor condition. Don’t wait for administrators to allocate more money to field maintenance, show them how their money would be used.

Administrators. Administrators should keep in mind that proper traffic control costs nothing in terms of dollars, and at the same time, offers the most effective means of reducing dangerously worn areas on game and practice fields. The administrator needs to clearly define the conditions for using the field at the beginning of each season. The game field should be reserved for games only. Be prepared to allocate resources on an annual basis for field maintenance, and on a less frequent basis for field renovation. It is important for the turf manager to keep the administrator up to date on what is best for the field. Also, the budget needs to be discussed at multiple points throughout the year with all parties involved.

With budgets shrinking, it is important to concentrate resources on high traffic or problem areas. The best way to combat issues is through site-specific management tools. Just by concentrating resources and incorporating site-specific management tools, you can reduce input in lower traffic areas and increase inputs on high traffic areas. High traffic areas require additional coring, seeding, fertility, and topdressing with amendments such as sand, calcined clay, or compost. The additional attention and resources can go a long way to providing a safe playing field for all.

Ryan Adams from Iowa State is the state’s Turfgrass Extension Associate, focused primarily on the commercial turfgrass industry. He can be reached at rsadams@iastate.edu.